Discover how spray foam kits offer versatile, cost-effective insulation for homes, workshops, and commercial spaces. Learn what makes them energy-efficient, where you can use them, and how to apply them safely for lasting results.

Outline:

– Understanding spray foam kits: components, types, and why they matter

– Performance and building science: R-values, air sealing, and moisture

– Where to use them: homes, workshops, and commercial spaces

– Cost and value: DIY vs. pro installation, yield, and payback

– Safety, step-by-step application, codes, and long-term care

Understanding Spray Foam Kits: What They Are and Why They Matter

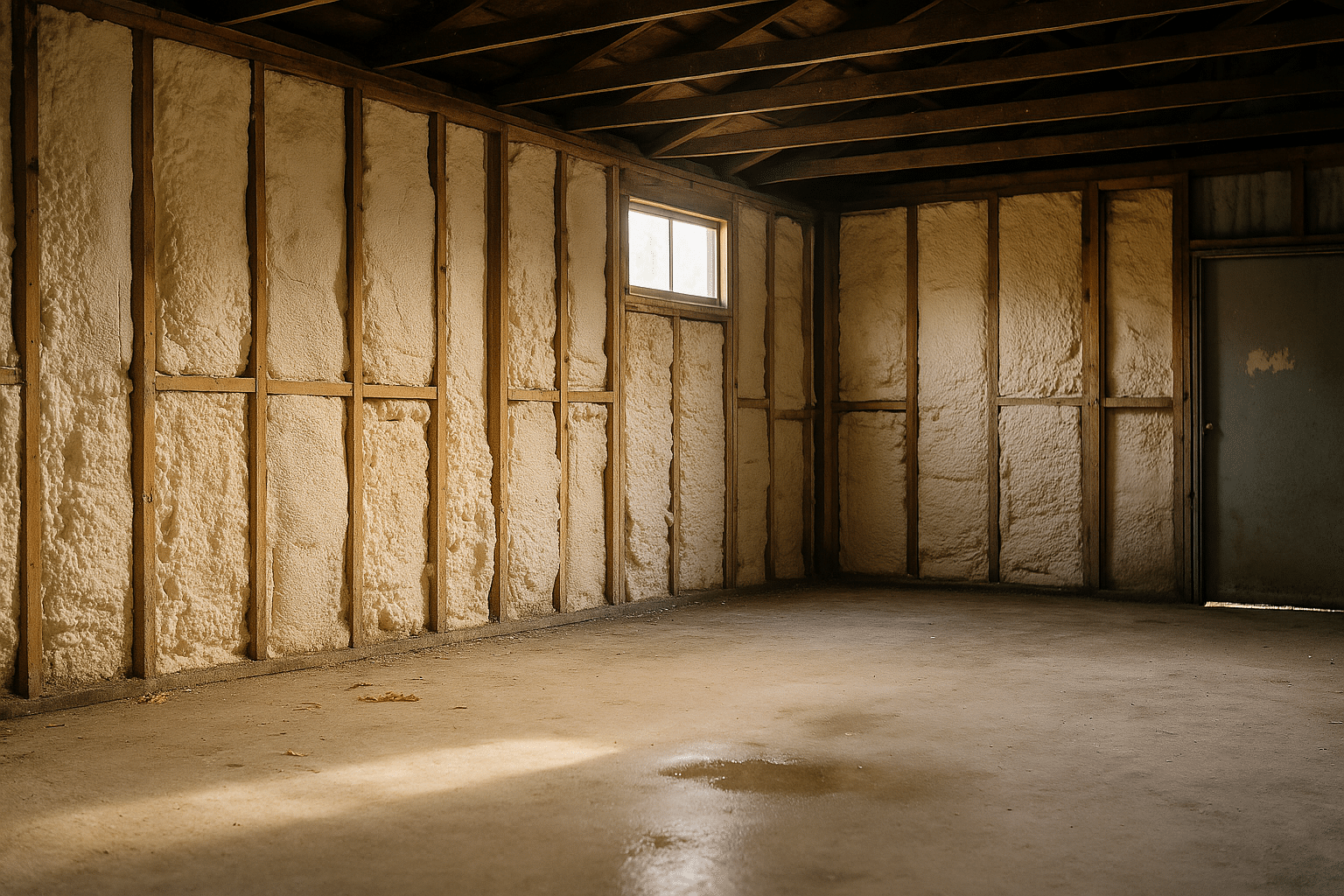

Spray foam kits are packaged, two-component systems that mix on demand at the spray gun, expanding into a rigid or semi-rigid foam that seals and insulates in one pass. The components—typically an isocyanate and a resin—travel through color-coded hoses, meet at the nozzle, and react within seconds to form a continuous, gap-filling layer. Unlike batt or blown-in products that depend on friction or density to stay put, cured foam adheres to most clean substrates, creating a durable air seal in hard-to-reach places. For homeowners, facilities managers, and tradespeople, this means fewer drafts, fewer cold spots, and a measurable improvement in comfort and energy performance.

There are two primary categories: open-cell and closed-cell. Open-cell foam is lighter and more vapor-permeable, often used for interior assemblies where sound control and cost efficiency are priorities. Closed-cell foam is denser, offers higher R-value per inch, and provides notable moisture resistance; it’s favored for rim joists, crawlspaces, metal walls, and areas that benefit from added structural rigidity. In either case, a kit allows you to control the where and the how much, making targeted upgrades—such as sealing a leaky attic hatch or insulating a garage partition—practical in a single afternoon.

Why does this matter? Heat loss and heat gain are relentless; they slip through cracks, wiring penetrations, rim joists, and around window frames. Traditional insulation slows heat transfer but can leave air pathways untouched. Foam excels because it insulates and air-seals simultaneously. When a continuous air barrier is combined with appropriate insulation levels, buildings often see reduced energy consumption, quieter interiors, and improved humidity control. For small projects and precise fixes, kits deliver agility: you use only what you need, exactly where it’s needed, without scheduling a truck or disrupting large areas of the building.

Quick highlights of what a kit can do:

– Air-seal cracks and penetrations around plumbing and electrical runs

– Insulate irregular cavities where batts don’t fit snugly

– Create continuous insulation layers on sheathing or metal panels

– Tackle phased projects at your own pace, area by area

Performance and Building Science: R-Values, Air Sealing, and Moisture Control

Insulation performance rests on two pillars: thermal resistance and air control. Closed-cell spray foam typically delivers about R-6 to R-7 per inch, while open-cell commonly lands around R-3.5 to R-4 per inch. Those values matter, but the standout advantage is air sealing. Even modest gaps—think a handful of quarter-inch cracks around a rim joist—can add up to the equivalent of an open window on a windy day. By expanding to fill voids, foam sharply limits uncontrolled airflow, which can reduce stack-effect drafts and lessen the workload on heating and cooling equipment.

Air leakage is often measured with blower door tests, reported as air changes per hour at 50 Pascals (ACH50). When a leaky attic floor or basement band joist is sealed with foam, projects commonly see meaningful ACH50 reductions, especially when sealing complements weatherstripping and dense-pack or batt insulation. The result is a more predictable indoor environment: temperatures stay steadier, humidity swings moderate, and dust infiltration drops. In mixed and cold climates, cutting uncontrolled airflow can help prevent condensation inside wall assemblies by keeping warm, moist indoor air out of cold cavities.

Moisture management is another essential element. Closed-cell foam’s low permeance can function as a vapor retarder at sufficient thickness, helping control diffusion in cold climates when installed on the warm side of the assembly. Open-cell foam is more vapor-open, which can be an advantage when drying potential is desired. The right choice depends on climate, assembly design, and code requirements. In many cases, foam is part of a layered strategy that includes exterior continuous insulation, interior drywall, and appropriate flashing details.

Comparing foam with other insulations is helpful:

– Fiberglass batts: cost-effective and familiar, but air leakage can bypass the thermal layer unless meticulous air sealing is added.

– Blown-in cellulose: good cavity fill and sound attenuation; still benefits from a separate air barrier to limit convective loops.

– Rigid foam boards: excellent continuous insulation on exteriors; joints require careful taping and sealing to prevent air leaks.

Used thoughtfully, spray foam kits give you a way to plug the air-leak holes in the system while adding meaningful R-value in a single step. That dual function is why many energy audits prioritize sealing with foam where it counts most: attics, rim joists, top plates, and penetrations.

Where to Use Spray Foam Kits: Homes, Workshops, and Commercial Spaces

One reason spray foam kits are so well-regarded is their flexibility. They target the chronic trouble spots found in real buildings—places where square corners are the exception and wires, pipes, and framing make neat insulation nearly impossible. In homes, workshops, and commercial properties, the same physics applies: stop air movement through the envelope, raise effective R-value where it matters, and protect vulnerable assemblies from moisture and temperature swings.

Common residential applications include:

– Attic floors and knee walls: Seal top plates, wire penetrations, and chases before adding loose-fill or batts above.

– Rim/band joists: A frequent source of winter drafts; foam adheres to masonry and wood to create a continuous gasket.

– Crawlspaces: Closed-cell along walls can limit ground moisture migration when combined with proper vapor barriers.

– Garage-to-house walls and ceilings: Improve comfort and reduce fumes moving into living spaces with thorough sealing.

Workshops and outbuildings often have metal skins, wide stud spacing, and shifting use patterns. Foam’s adhesion to metal panels and irregular substrates makes it a standout option for:

– Metal walls and roof decks: Control condensation by keeping the interior panel temperature above the dew point.

– Doors and seams: Target small but numerous leaks around overhead door tracks and panel joints.

– Partition walls: Reduce noise transfer between shop areas and storage or office zones.

In commercial settings, kits are useful for focused tasks between larger phases of construction or maintenance:

– Mechanical rooms: Seal pipe and conduit penetrations to increase firestop integrity when paired with approved assemblies.

– Refrigerated areas: Closed-cell layers help maintain stable temperatures and reduce frost potential on cold surfaces.

– Tenant fit-outs: Quick air-sealing around new penetrations before ceilings close saves downstream troubleshooting.

Climate and code guide placement. In cold regions, interior-side vapor control may be critical; in hot-humid areas, controlling warm, moist exterior air from infiltrating cooler interiors is the priority. Unfinished foam typically must be protected by an approved thermal barrier—often 1/2-inch gypsum—in occupiable areas, or an ignition barrier in attics and crawlspaces used only for service access. Always confirm local requirements, especially for fire ratings and smoke development. With those boxes checked, spray foam kits offer targeted, reliable improvements across a wide range of building types without overhauling entire assemblies.

Cost, Yield, and Value: DIY vs. Pro Installation

Budget planning for spray foam starts with a simple unit: the board foot—one square foot at one inch thick. Kit yields are advertised in board feet, but real-world coverage usually runs 10–20% lower due to temperature, technique, and substrate irregularities. As a ballpark, DIY kits often pencil out to roughly $1.10–$2.00 per board foot in material cost, depending on kit size and region. Professional installation for closed-cell commonly ranges around $2.50–$4.00 per board foot, while open-cell pro installs may be closer to $1.10–$2.00 per board foot. Prices fluctuate with labor markets, supply chains, and project scale.

How do you judge value? Consider the energy you’ll save, the durability of the air seal, and the avoided callbacks or rework. Sealing a leaky rim joist or attic plane can cut drafts that would otherwise push your heating system to cycle more often. Many retrofits that combine air sealing with appropriate insulation upgrades see meaningful reductions in annual energy use, especially in climates with large heating or cooling loads. While every building is different, a targeted foam project can contribute to payback timelines that range from a few years to the length of a typical ownership horizon, influenced by utility rates and the size of the improvement.

DIY or pro? Use these decision points:

– Project size: Small to mid-size sealing jobs are DIY-friendly; whole-house cavity fills favor pro crews.

– Access and complexity: Tight, high, or hazardous spaces often justify a professional team and lift equipment.

– Finish requirements: If code requires thermal or ignition barriers with specific coatings or assemblies, pros may streamline compliance.

– Schedule: Pros can mobilize and complete large areas quickly; DIY allows phased work on weekends.

– Risk tolerance: If you’re new to two-component foams, start with test areas or hire a pro for critical zones.

Comparisons with alternatives sharpen the picture. Fiberglass and cellulose usually win on initial cost per R, but foam’s air sealing can lift the effective performance of the whole assembly. Rigid foam boards are strong on continuous insulation, though detailing around fasteners, edges, and penetrations takes time and care. By contrast, a spray-applied layer can wrap around irregularities in minutes. The result is not just an R-value on paper, but a tighter, calmer building that uses energy more efficiently day after day.

Safety, Installation Steps, and Long-Term Care

Spray foam kits reward careful preparation. Read the instructions fully, then stage the space with ventilation, drop cloths, and all required protective gear. Most kits recommend ambient and substrate temperatures in a moderate range—commonly around 60–80°F—and dry surfaces free of oils, dust, and frost. Humidity should be controlled to reduce the chance of surface condensation. Personal protective equipment matters: chemical-resistant gloves, full-coverage clothing, eye protection, and a suitable respirator are standard. If you can smell or see overspray in the air, your respiratory protection and ventilation need attention.

Follow a proven application sequence:

– Warm and shake components as directed; balanced temperature helps maintain proper mix and spray pattern.

– Test-spray onto scrap; confirm color, texture, and expansion before moving to the actual surface.

– Work in thin lifts, typically around 1 inch for closed-cell and somewhat thicker for open-cell, allowing recommended cure time between passes.

– Keep the gun moving; consistent distance and speed prevent voids, drips, and overly dense sections.

– Trim cured foam flush where required, and dispose of offcuts per local regulations.

Health and re-entry guidelines come from the kit manufacturer, and many recommend a ventilated cure period—often measured in hours—before unprotected occupants return. Fresh foam should not be left exposed in living areas; building codes typically require a 15-minute thermal barrier such as gypsum board, or an approved alternative, to limit fire risk. In attics and crawlspaces used only for service, an ignition barrier may be acceptable—verify locally.

Common pitfalls to avoid:

– Spraying too thick in one pass, which can cause improper cure or scorching

– Ignoring temperature limits, leading to poor adhesion or shrunken foam

– Skipping air-seal detailing at edges and penetrations

– Leaving foam exposed where a thermal or ignition barrier is required

– Underestimating ventilation needs during and after application

Long-term care is straightforward. Once cured and protected by the proper barrier, foam is stable and requires little maintenance. Inspect annually for mechanical damage, UV exposure at edges, or pest activity in adjacent materials, and touch up as needed. Environmentally, look for kits that use low global-warming-potential blowing agents and consider waste planning so empties are properly depressurized and recycled where programs exist. With a thoughtful approach to safety, technique, and code compliance, a spray foam kit can deliver reliable, long-lived performance that you can feel every time the weather turns extreme.